Complete Robotics & Automation Solutions

Robomec Solutions offers a wide range of cutting-edge industrial automation systems designed to meet the dynamic demands of Saudi Arabia’s rapidly evolving manufacturing sector. Our solutions, including advanced Delta robots, collaborative cobots, high-efficiency palletizing units, and precision conveyor systems, are engineered to transform production floors into highly efficient, agile, and intelligent environments. We leverage the latest advancements in automation technology to streamline operations, reduce costs, and enhance overall productivity. Our team works closely with clients to design, integrate, and deploy customized solutions that align with their specific needs, ensuring a seamless transition to a more automated and streamlined production process.

Our conveyors and robotic systems are at the heart of our automation offerings. From high-speed, modular conveyors designed for versatility and scalability to specialized robots that handle complex tasks like welding, assembly, and inspection, we provide solutions that increase throughput while maintaining the highest levels of precision and safety. Whether it’s a fully automated material handling system, a flexible robotic arm for assembly lines, or a complete end-to-end solution for product inspection, our systems ensure that industries such as automotive, electronics, and food processing experience a marked improvement in operational efficiency and quality control.

As industries move toward the future, the need for smarter, more adaptable systems has never been greater. Robomec Solutions is committed to helping businesses modernize their operations by providing high-quality, future-ready automation solutions. Our systems are scalable, customizable, and built with flexibility in mind to accommodate future growth and technological advancements. From automating routine tasks to integrating complex robotic systems into existing infrastructures, we are the trusted partner in your journey toward enhanced operational efficiency, reduced downtime, and sustainable growth.

Robots

Industrial Robots

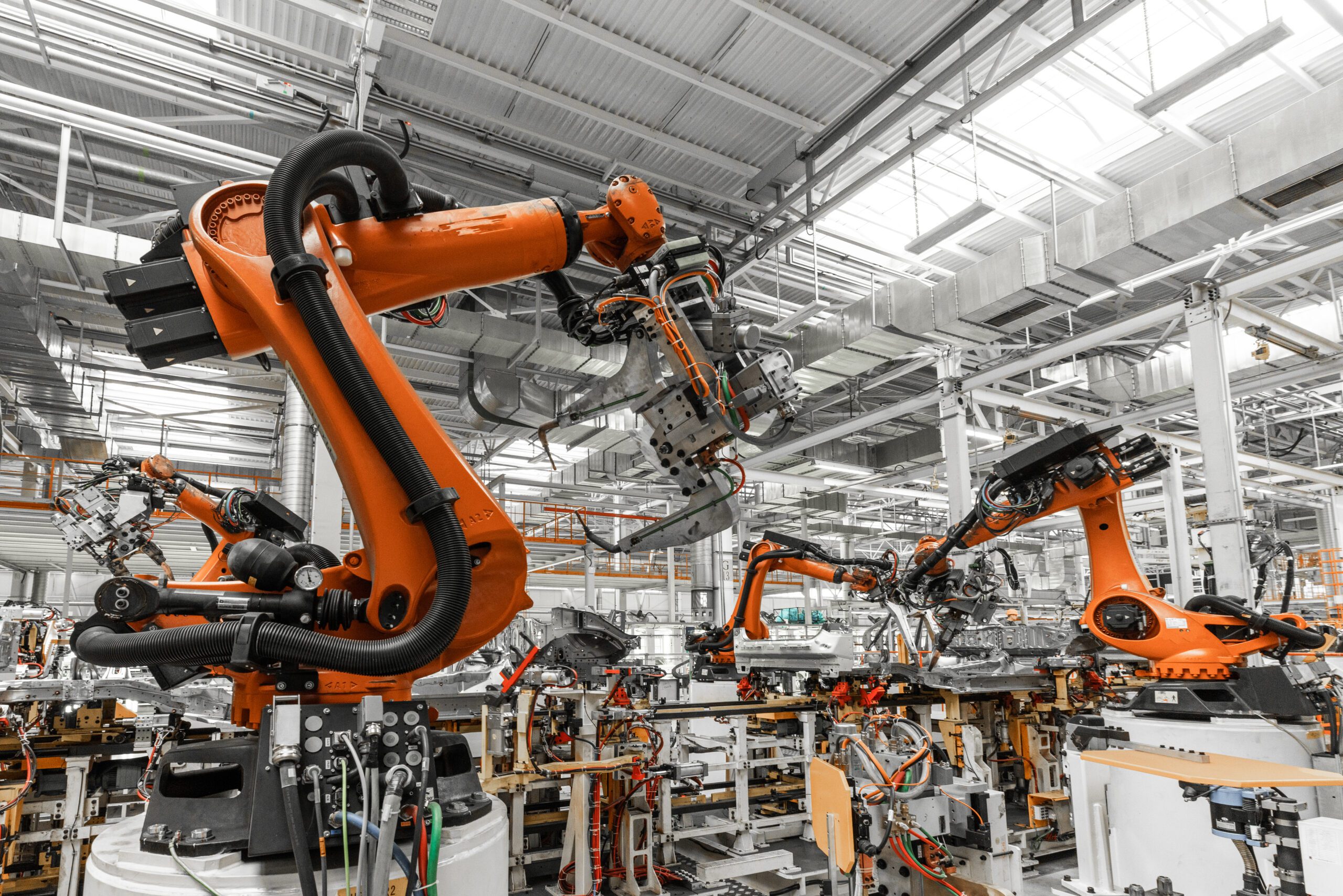

Industrial robots are large, heavy-duty machines positioned in fixed locations within a production facility. They are primarily used to automate intensive tasks, particularly in assembly lines where high-volume, repetitive actions are necessary. These robots can perform tasks such as welding, painting, assembly, and material handling with high precision, improving both the speed and consistency of production. Their ability to work around the clock without breaks allows for continuous, high-efficiency operations, drastically increasing the overall output of manufacturing processes.

The adoption of industrial robots brings significant advantages, including improved quality and reduced human errors. Robots provide consistent and precise output, ensuring nearly flawless mass production of products. This high level of accuracy minimizes raw material wastage, optimizes operational costs, and enhances customer satisfaction. Moreover, industrial robots contribute to the reduction of labor costs, as they can replace multiple workers and operate in environments that might be hazardous or unsuitable for human workers, such as high-temperature areas or locations with toxic fumes.

Additionally, industrial robots offer enhanced safety by taking on dangerous tasks, protecting workers from potential harm. Their use in hazardous environments, such as welding or handling toxic substances, reduces the risk of workplace injuries and legal liabilities. Beyond safety, robots improve profitability by reducing downtime and increasing productivity. With their flexibility, industrial robots can be easily programmed to adapt to various tasks, making them a valuable asset in industries like automotive and aerospace. Their consistent performance and ability to operate without rest or fatigue make them essential for optimizing manufacturing processes and meeting high-demand production targets.

Articulated Robots

The Industrial Backbone of Precision, Power, and Versatility

Articulated Robots are the most widely adopted form of industrial automation, known for their arm-like structure and broad motion capabilities. These robotic systems feature multiple rotary joints—also called axes—that offer flexible, multi-directional movement much like the human shoulder, elbow, and wrist. Their structural adaptability and precise control make them indispensable across sectors like automotive, electronics, heavy manufacturing, and general assembly.

At Robomecs, we offer a portfolio of advanced articulated robots engineered to meet the rigorous demands of high-precision operations, from high-payload material handling to fine-detail arc welding. Whether it’s a compact 4-axis unit or a robust 6-axis robot with a 1,000 kg payload, our articulated solutions deliver repeatability, range, and durability.

Scara Robots

Precision and Speed for High-Throughput Assembly Tasks

SCARA (Selective Compliance Articulated Robot Arm) robots are purpose-built for fast, repeatable assembly and pick-and-place applications where precision in the horizontal plane (X-Y) is critical, while maintaining rigidity along the vertical (Z) axis. Introduced in the early 1980s, SCARA robots quickly became a mainstay in electronics and precision manufacturing environments due to their unmatched speed, compact design, and exceptional repeatability.

At Robomecs, we specialize in deploying SCARA robot systems optimized for high-speed tasks such as PCB assembly, microelectronics handling, and product inspection. Their four-axis architecture and minimal footprint make them ideal for space-constrained production lines and applications demanding ultra-short cycle times.

Delta Robots

Ultra-High-Speed Precision for Pick-and-Place & Sorting

Delta Robots are engineered for lightning-fast pick-and-place operations where throughput, precision, and footprint optimization are critical. Recognizable by their spider-like parallel arm structure, Delta robots are uniquely suited for top-mounted, high-speed applications requiring minimal inertia and exceptional responsiveness.

At Robomecs, we offer advanced Delta robot solutions for industries that demand ultra-high-speed handling—such as food processing, pharmaceuticals, electronics, and lightweight packaging. Their parallel kinematic design enables up to 300+ cycles per minute, allowing manufacturers to significantly increase line speeds without sacrificing accuracy.

Cartesian Robots

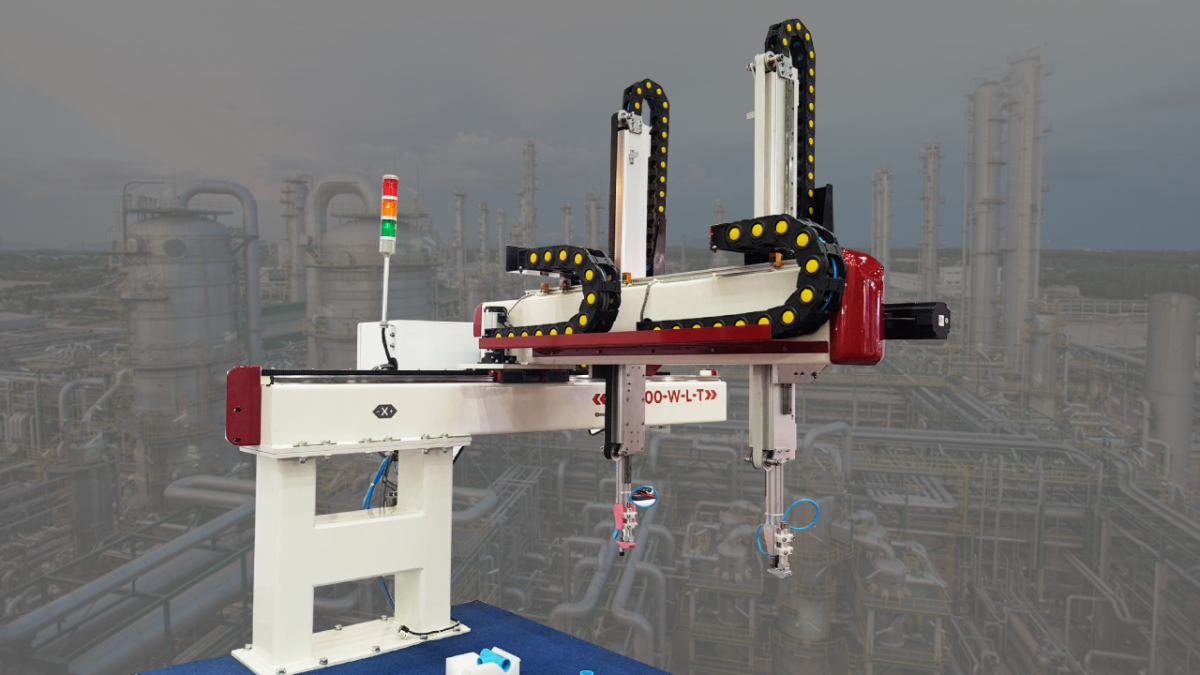

Heavy-Duty Precision with Scalable Linear Motion

Cartesian Robots—also known as Gantry Robots or Linear Robots—are ideal for applications demanding precise linear motion, heavy payload handling, and customizable workspace coverage. Built on an orthogonal X-Y-Z axis framework, these robots deliver unmatched control and accuracy for tasks such as material transfer, CNC machine loading, palletizing, and large-scale assembly.

At Robomecs, we deploy Cartesian systems tailored to industrial needs ranging from aerospace part handling to automated dispensing and welding. Their rigid structure, high payload capacity, and programmable modularity make Cartesian robots one of the most flexible automation platforms in modern industry.

Collaborative Robots

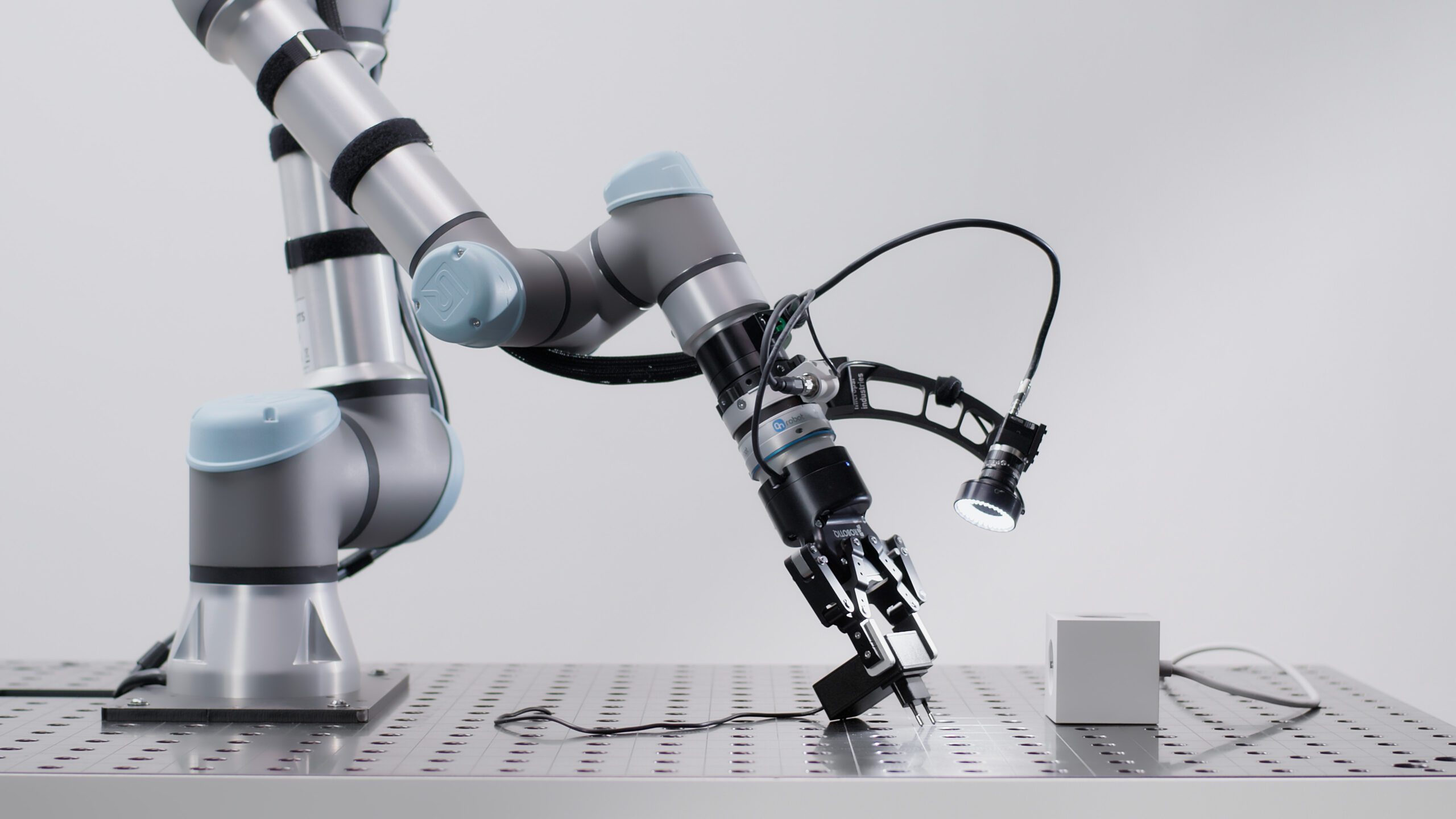

Collaborative Robots are also addressed as ‘Cobots’ in the Industrial World. These robots are known to take the regular operation standards of a company to a top-notch level. They improve the productivity, flexibility and security of operating and performing functions whilst working hand-in-hand with their human counterparts. As the name implies, Cobots work collaboratively alongside humans with great agility, effectiveness and efficiency.

They are primarily used to handle small parts, complete simple tasks, inspect products and other functions that require the intuitions and support of a human mind and body. Cobots are mainly used to complete actions like dispensing, assembling, tending, finishing, welding, removing, inspecting and more.

There are many types of collaborative robots; four of the major types of collaborative robots are ‘Hand Guiding’, ‘Speed and Separation’, ‘Safety Monitored Stop’ and ‘Power and Force Limiting’. They are categorised based on their functionalities and the unique technology blends they harness. The general feature of all these robots is that to operate efficiently they require a degree of safe and secured human interaction.

There are also a few cons to utilising Cobots in your factories. These robots require a restricted and large working area to ensure a comfortable and secure working environment for their human counterparts. Also, since these robots rely on humans compared to other robots, they are not very useful without human supervision or assistance. Furthermore, Cobots are usually slower during operations, especially when the working area is advanced to ensure the operator’s safety Force-Limited Cobots

- Torque sensors enable safe human contact in assembly and polishing.

- No safety cages reduce deployment costs for SMEs.

Mobile Cobots

Agile. Intelligent. Human-Centric Automation.

Mobile Cobots combine the collaborative functionality of robotic arms with the autonomous mobility of AMRs (Autonomous Mobile Robots), creating a new class of intelligent automation capable of navigating, manipulating, and collaborating—all in one solution.

At Robomecs, our Mobile Cobots are designed for dynamic, fast-paced environments such as warehouses, assembly lines, and manufacturing facilities where flexibility and adaptability are key. These systems autonomously navigate complex floor layouts, identify and manipulate parts or tools, and interact safely with human coworkers—all without requiring fixed infrastructure like conveyors or safety cages.

AI-Integrated Cobots

Smarter Robots for Complex, Adaptive Workflows

AI-Integrated Cobots represent the cutting edge of robotic automation—melding advanced machine learning, computer vision, and cognitive processing into collaborative robots that not only perform tasks, but understand them. These intelligent systems excel in environments that require adaptability, decision-making, and real-time quality control.

At Robomecs, our AI-powered collaborative robots go beyond basic automation. They see, learn, and react dynamically to complex variables on the shop floor. From identifying randomly placed items in cluttered bins to inspecting microscopic defects on high-speed lines, our AI-Integrated Cobots are transforming how industries handle variability and precision.

Mobile Robots

A Mobile Robots, designed for material transport, are autonomous or guided systems that automate the movement of goods within industrial environments such as warehouses, manufacturing plants, and distribution centers. These robots are an essential part of modern logistics, offering flexibility, efficiency, and scalability in material handling. Whether autonomous mobile robots (AMRs) that use AI-powered navigation and sensors to detect and avoid obstacles, or automated guided vehicles (AGVs) that follow predefined paths or tracks, these robots significantly enhance material flow and operational efficiency.

These robots are primarily used to move goods, ranging from small items to large pallets, and are ideal for repetitive tasks like material transport, order picking, and sorting. The autonomous robots adapt to changes in their environment and optimize their routes in real-time, reducing downtime and human labor. They integrate seamlessly into existing workflows, and some systems even allow robots to be reprogrammed or rerouted based on operational demands, such as shifts in production schedules or storage layouts.

Although mobile robots are highly efficient and can work 24/7, they do require sufficient space for smooth operation. Additionally, their deployment and maintenance require careful integration into existing systems. One significant advantage is their ability to work autonomously, reducing human involvement in low-risk tasks and allowing workers to focus on more complex or value-added functions. However, the technology still requires oversight and human intervention for tasks that go beyond the robots’ capabilities. Mobile robots for material transport help improve throughput, reduce operational costs, and enhance safety by minimizing manual handling and human errors.

Autonomous Mobile Robots (AMRs)

Intelligent, Flexible Transport for Dynamic Environments

Autonomous Mobile Robots (AMRs) are AI-driven transport units designed to move materials across industrial, commercial, and healthcare environments without human intervention or fixed infrastructure. Unlike AGVs (Automated Guided Vehicles), AMRs use advanced sensors, cameras, and SLAM (Simultaneous Localization and Mapping) to dynamically navigate around obstacles, adapt to floor traffic, and optimize delivery paths in real-time.

At Robomecs, we integrate AMR solutions into smart factories, logistics centers, and warehouses for applications like parts delivery, cart towing, and materials replenishment. Whether you need lightweight totes moved between stations or large components transported across bays, AMRs offer a safe, scalable, and efficient alternative to traditional conveyance systems.

Forklift Robots

Autonomous Material Handling for Efficient Warehouse Operations

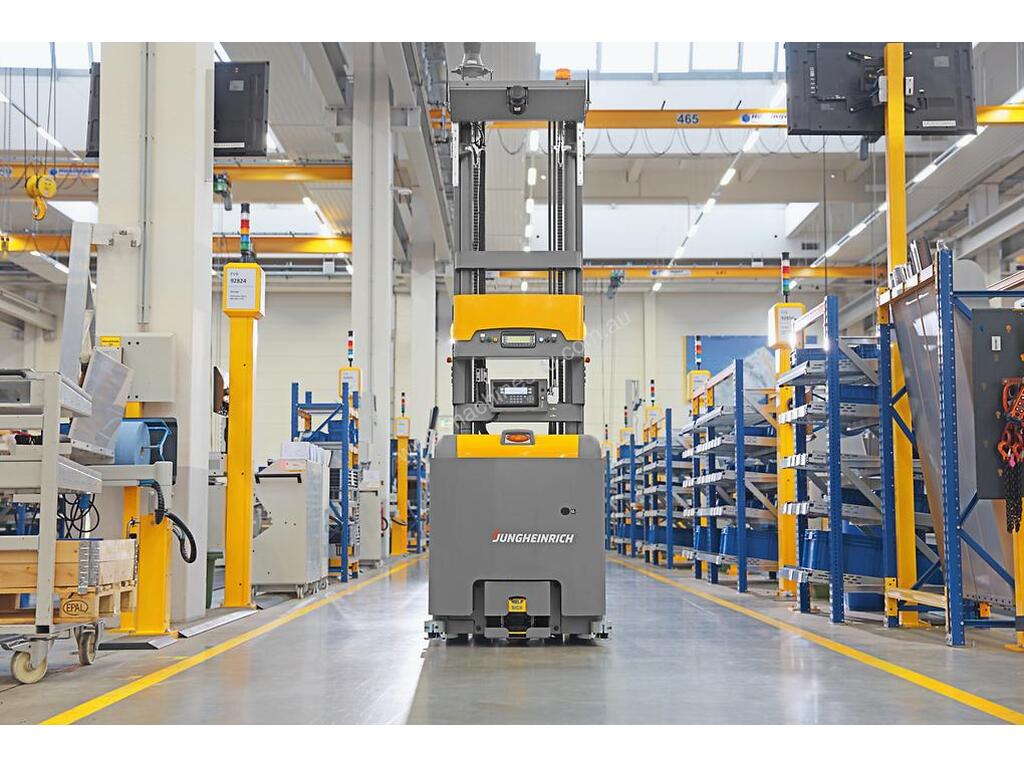

Forklift robots are autonomous mobile systems designed to transport and handle pallets and heavy materials within warehouse and distribution center environments. Equipped with advanced laser and vision guidance technologies, these robots are capable of precise navigation in narrow aisles, seamlessly integrating with warehouse management systems (WMS) to optimize inventory flow and order fulfillment.

At Robomecs, we specialize in deploying forklift robots that improve space utilization, reduce human error, and enhance productivity by automating the most labor-intensive tasks, such as loading/unloading, pallet transport, and storage retrieval. These robots can carry out end-to-end material handling, ensuring goods are moved efficiently across the warehouse with minimal downtime.

Automated Guided Vehicles (AGVs)

Reliable, High-Capacity Transport for Structured Workflows

Automated Guided Vehicles (AGVs) are track-based transport robots that follow predefined paths—typically using magnetic strips, embedded wires, QR codes, or reflective tape—to move materials within structured environments. These systems excel in environments with consistent, repeatable routes, making them a go-to solution for heavy-duty transport and fixed-route logistics in large factories and distribution centers.

At Robomecs, we deploy AGV systems that can handle up to 5,000 kg payloads, automating tasks like pallet handling, raw material delivery, and warehouse-to-production line transfers. Designed for reliability and safety, AGVs reduce manual intervention, minimize error, and optimize transport workflows where path consistency is preferred.

Specialized Process Robots

Specialized Process Robots are highly advanced robots tailored for specific tasks within industrial processes, designed to deliver exceptional performance in niche applications. These robots are engineered to optimize productivity, precision, and consistency in processes that require specialized capabilities beyond general-purpose automation. They are commonly found in industries such as automotive manufacturing, electronics assembly, pharmaceuticals, and food processing, where precision and efficiency are paramount.

These robots are specifically programmed and equipped with tools and sensors that make them highly effective for tasks like welding, painting, packaging, dispensing, and testing. For example, specialized welding robots excel in precise, high-quality welding of complex parts, while painting robots ensure uniform application of coatings with minimal material waste. These robots are often equipped with advanced sensors that allow them to adapt to variations in the process, maintaining the required quality standards throughout the production cycle.

Specialized process robots offer several benefits, including increased operational efficiency, reduced error rates, and enhanced safety by taking on dangerous or repetitive tasks. Their integration into production lines leads to improved throughput, higher consistency, and lower labor costs. However, these robots often require significant initial investment and may need to be highly customized, which can make them less flexible in applications that demand a variety of tasks. Despite these challenges, their ability to perform complex, specialized functions with unparalleled precision makes them invaluable in industries requiring high standards of process control.

Welding Robots

Precision Welding for High-Quality Manufacturing

Welding robots are advanced robotic systems designed for arc welding and spot welding applications, commonly used in industries such as automotive manufacturing, aerospace, and metalworking. These robots provide exceptional precision and repeatability, ensuring high-quality welds with sub-millimeter accuracy. With the integration of seam tracking sensors and adaptive welding technology, welding robots can adjust in real-time to part variations, delivering consistent and precise results across production runs.

At Robomecs, we specialize in deploying welding robots optimized for high-volume manufacturing environments, where accuracy and efficiency are paramount. Whether it’s welding automotive chassis, aerospace components, or industrial metal structures, our welding robots improve throughput, enhance weld quality, and reduce the need for manual intervention.

Painting Robots

Precision Coating for High-Quality Finishes

Painting robots are specialized systems designed to deliver uniform coating applications across a variety of industrial and commercial products, including automotive parts, aerospace components, and consumer goods. By utilizing HVLP (high-volume, low-pressure) technology, these robots ensure precise application with minimal overspray, enhancing both finish quality and material efficiency. They play a crucial role in reducing material waste and improving productivity in mass-production environments.

At Robomecs, we offer painting robot solutions designed for consistent, high-quality finishes with optimal paint usage, making them ideal for industries where coating precision and repeatability are critical. Our systems are highly customizable, with features such as real-time adaptive control and automated paint mixing, making them a versatile choice for many industries.

Inspection Robots

Precision Quality Control with AI-Enhanced Defect Detection

Inspection robots are integral to ensuring the highest quality standards in manufacturing by detecting defects and flaws with precision, down to as small as 0.1mm. These robots typically leverage vision-based quality control (QC) systems combined with AI-powered analytics to not only identify defects but also classify them and trigger rework alerts. This advanced automation ensures that products meet stringent quality standards while minimizing human error.

At Robomecs, we specialize in delivering inspection robot systems that integrate cutting-edge machine vision and AI analytics for real-time defect detection and actionable insights. These robots are ideal for industries that require precision inspection and rapid defect classification, including electronics, automotive, pharmaceuticals, and consumer goods manufacturing.

Conveyor

Belt Conveyors

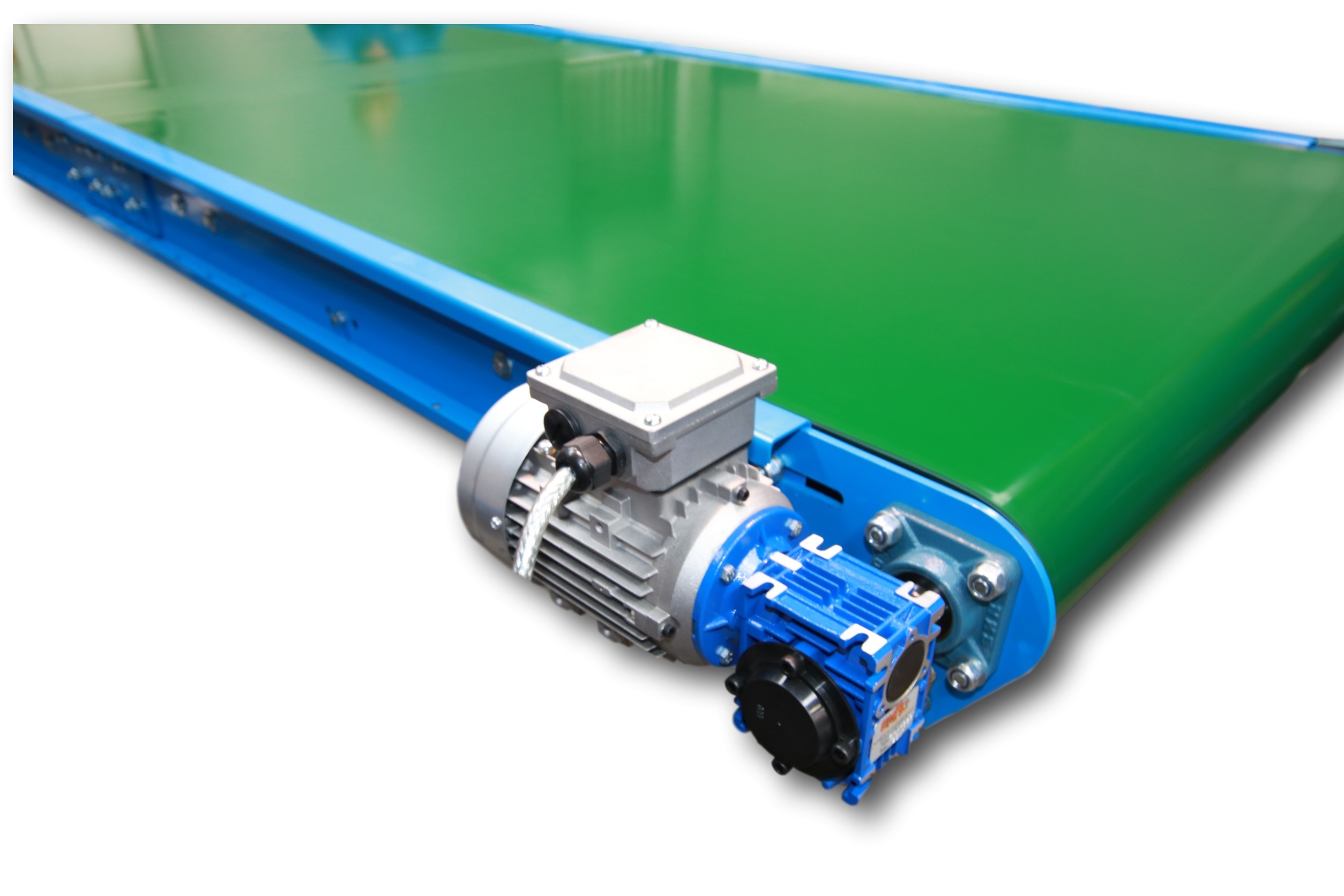

Flat Belt Conveyors

Flat Belt Conveyors are one of the most versatile and widely used conveyor systems in industries that require the smooth transport of goods such as boxes, parcels, and packaged products. With their seamless belt surface, these conveyors ensure that items are moved reliably without causing damage or jamming, making them ideal for industries like logistics, e-commerce, and food packaging.

At Robomecs, we provide custom-designed Flat Belt Conveyors that are optimized for your specific needs. Their modular construction allows for easy configuration and integration with other systems like sorting mechanisms, packaging machines, and automated lines. Whether you’re handling lightweight parcels or larger product packages, our flat belt conveyors are designed to improve throughput while minimizing downtime and maintenance

Cleated/Incline Belt Conveyors

Cleated/Incline Belt Conveyors are designed to transport products efficiently at steep angles without the risk of slippage, making them ideal for industries that require vertical movement of bulk materials or packaged goods. These conveyors feature cleated belts that secure items in place, even on inclines of up to 45°, allowing for smooth and safe transport.

At Robomecs, we specialize in Cleated/Incline Belt Conveyors that are engineered to meet the unique demands of industries like agriculture, food processing, and manufacturing. These systems are designed for handling everything from grains and fruits to large bags and heavy-duty materials, ensuring maximum product safety and minimal downtime.

Food-Grade Belt Conveyors

Food-Grade Belt Conveyors are specifically designed to meet the stringent hygiene and safety standards required in the food processing industry. Manufactured from FDA and USDA-approved materials such as PU (polyurethane) and PVC, these conveyors are ideal for transporting food products such as meat, dairy, baked goods, and packaged foods. With easy-clean designs and minimal crevices, they ensure compliance with food safety regulations, preventing contamination during transport.

At Robomecs, we provide Food-Grade Belt Conveyors tailored to the unique needs of the food industry, offering reliable, hygienic, and efficient transport solutions for food processing, e-commerce, and agricultural sectors. Our systems are designed to maximize productivity while adhering to the highest food safety standards.

Roller Conveyors

Gravity Roller Conveyors

Gravity Roller Conveyors offer a simple yet effective material handling solution where power is not required. By relying on gravity to move products, these conveyors help reduce operational costs, particularly in manual loading and unloading zones. They are perfect for transporting various product types such as cartons, boxes, and crates without the need for electrical power.

At Robomecs, we design Gravity Roller Conveyors that provide cost-effective, reliable, and efficient solutions for warehouses, distribution centers, and manual handling operations, making them ideal for environments with minimal automation.

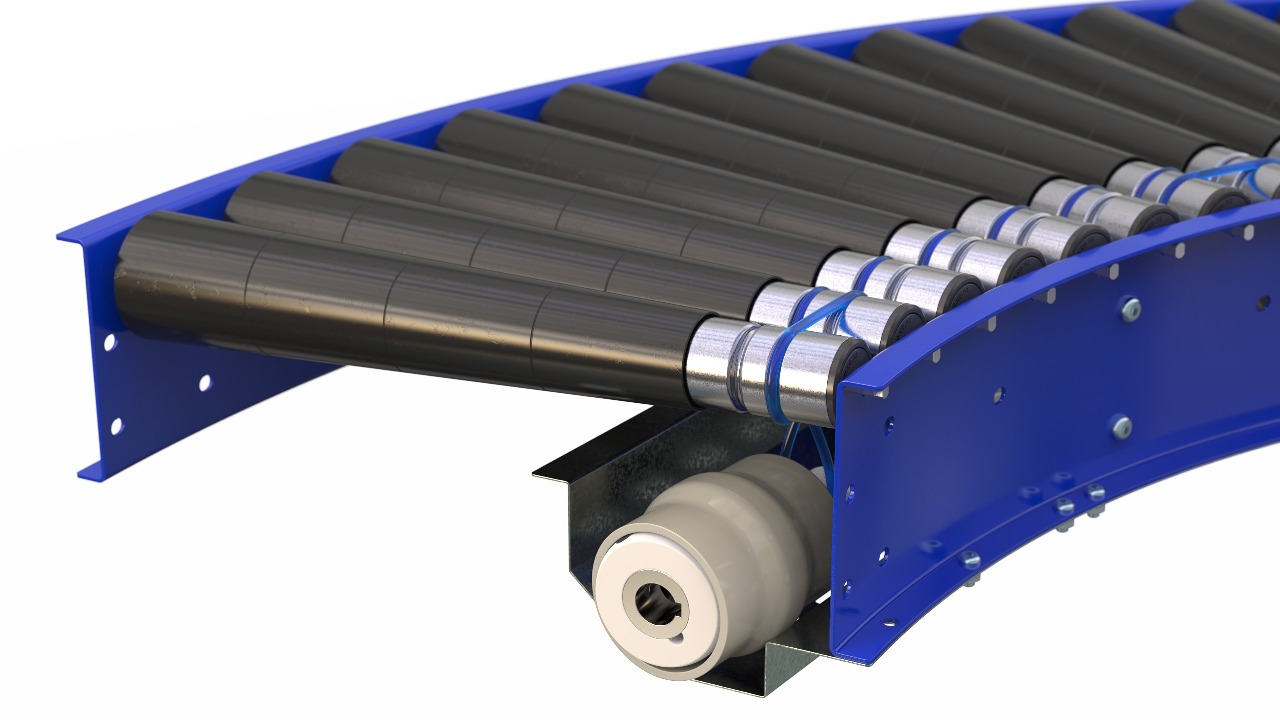

Powered Roller Conveyors

Powered Roller Conveyors are an essential component in material handling systems, offering motorized zones that enable precise control over the movement of goods. These conveyors are especially beneficial in environments where accumulation and merging of heavy items, such as pallets, are required. Powered Roller Conveyors help automate the process of transporting large and heavy loads, making them ideal for use in manufacturing plants, distribution centers, and warehouses.

At Robomecs, we design Powered Roller Conveyors that provide reliable, efficient, and controlled movement for heavy-duty applications, ensuring smooth and consistent transport of products with high load capacities.

Flexible Roller Conveyors

Flexible Roller Conveyors provide the versatility needed for dynamic environments where layout changes are frequent and the need for portable solutions is essential. These conveyors are designed to offer expandable and retractable frames that easily adapt to temporary setups, making them ideal for situations such as loading and unloading trucks or containers. With the ability to quickly adjust to different configurations, they are particularly valuable in industries like logistics, e-commerce, and retail, where speed and flexibility are key to operational success.

At Robomecs, we offer flexible roller conveyors that combine portability with high efficiency, providing a customizable solution for various material handling applications.

Chain-Driven Roller Conveyors

Chain-Driven Roller Conveyors are engineered to handle the toughest industrial environments, offering a reliable solution for moving heavy, bulky, or palletized materials such as pallets and drums. The durable chain-driven mechanism ensures consistent power transmission and precise control over the movement of heavy goods, making these conveyors ideal for applications in warehousing, automotive assembly, and heavy industries. Built for long-term use with minimal maintenance, they are designed to withstand high-stress conditions, ensuring productivity and operational efficiency.

At Robomecs, we offer top-tier chain-driven roller conveyors that provide heavy-duty performance with minimal downtime, delivering a powerful solution for your material handling needs.

Modular Plastic Chain Conveyors

Multi-Track Conveyors

Modular Plastic Multi-Track Conveyors are designed to provide versatile and efficient solutions for high-speed sortation tasks in environments like parcel hubs, distribution centers, and e-commerce fulfillment centers. With their unique modular design, these conveyors offer the flexibility to adapt to changing layouts and sorting requirements. Their diverging lanes ensure smooth and rapid sortation, making them ideal for environments that demand quick and reliable movement of goods.

At Robomecs, we specialize in providing modular plastic multi-track conveyors that deliver optimal flexibility, speed, and reliability, helping your operations stay efficient and scalable.

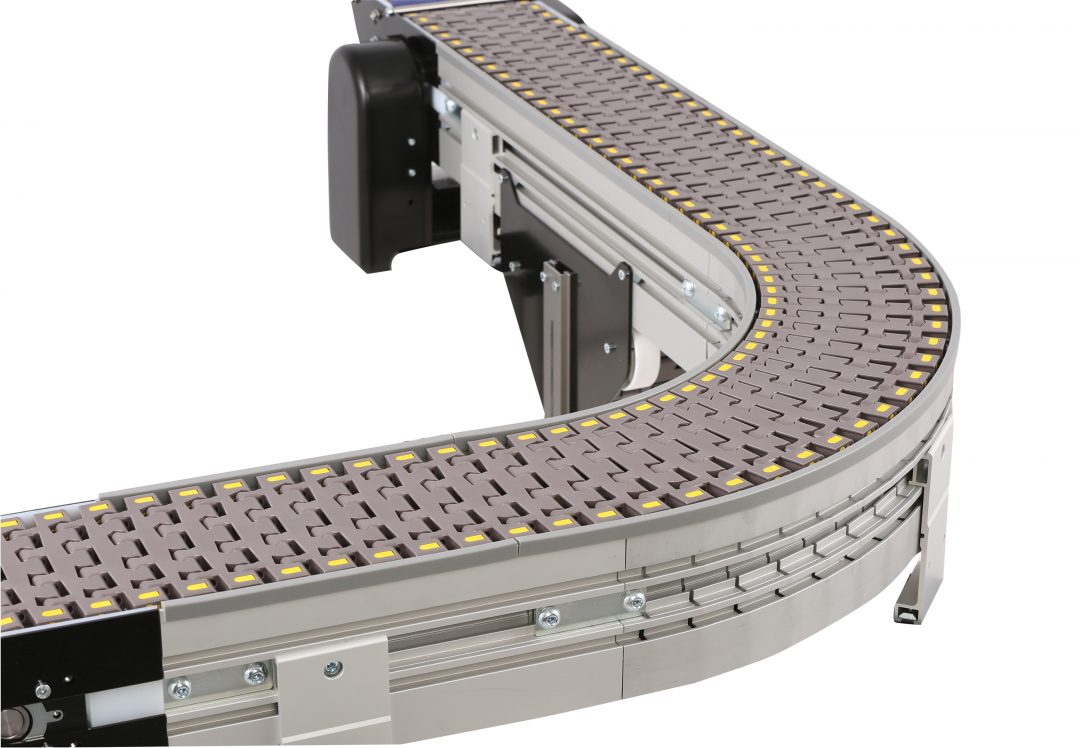

Curve Conveyors

Modular Plastic Curve Conveyors are designed to seamlessly integrate with your existing conveyor systems, enabling smooth directional changes while maintaining high throughput. These conveyors are perfect for optimizing floor space in facilities where every inch counts. Whether you’re navigating tight corners or creating efficient flow paths, modular plastic curve conveyors provide a versatile, wear-resistant solution.

At Robomecs, we offer modular plastic curve conveyors that make turning your products easy, with low maintenance needs, and highly adaptable designs that can fit any production line or warehouse layout.

Washdown Conveyors

Modular Plastic Washdown Conveyors are designed to meet the stringent demands of industries where cleanliness and hygiene are paramount. With an IP69K rating for high-pressure cleaning, these conveyors are built to withstand the toughest washdown procedures, making them the ideal choice for environments like meat and poultry processing plants. The system’s drainage channels ensure effective liquid flow, preventing pooling and maintaining food safety standards.

At Robomecs, we provide modular plastic washdown conveyors that are engineered to simplify cleaning and enhance safety in food processing and other high-standards environments.

Specialized Conveyors

Spiral Conveyors

Spiral conveyors are designed to handle vertical transportation with a minimal footprint, making them ideal for maximizing space in fulfillment centers, warehouses, and production facilities. These conveyors provide a gentle, continuous flow of products, ensuring that even fragile items like glass bottles are moved securely without damage. By utilizing vertical elevation, spiral conveyors help optimize your facility’s layout and improve operational efficiency.

At Robomecs, we offer high-quality spiral conveyors that combine space-saving design with smooth and reliable product handling for a variety of industries, from e-commerce to food processing.

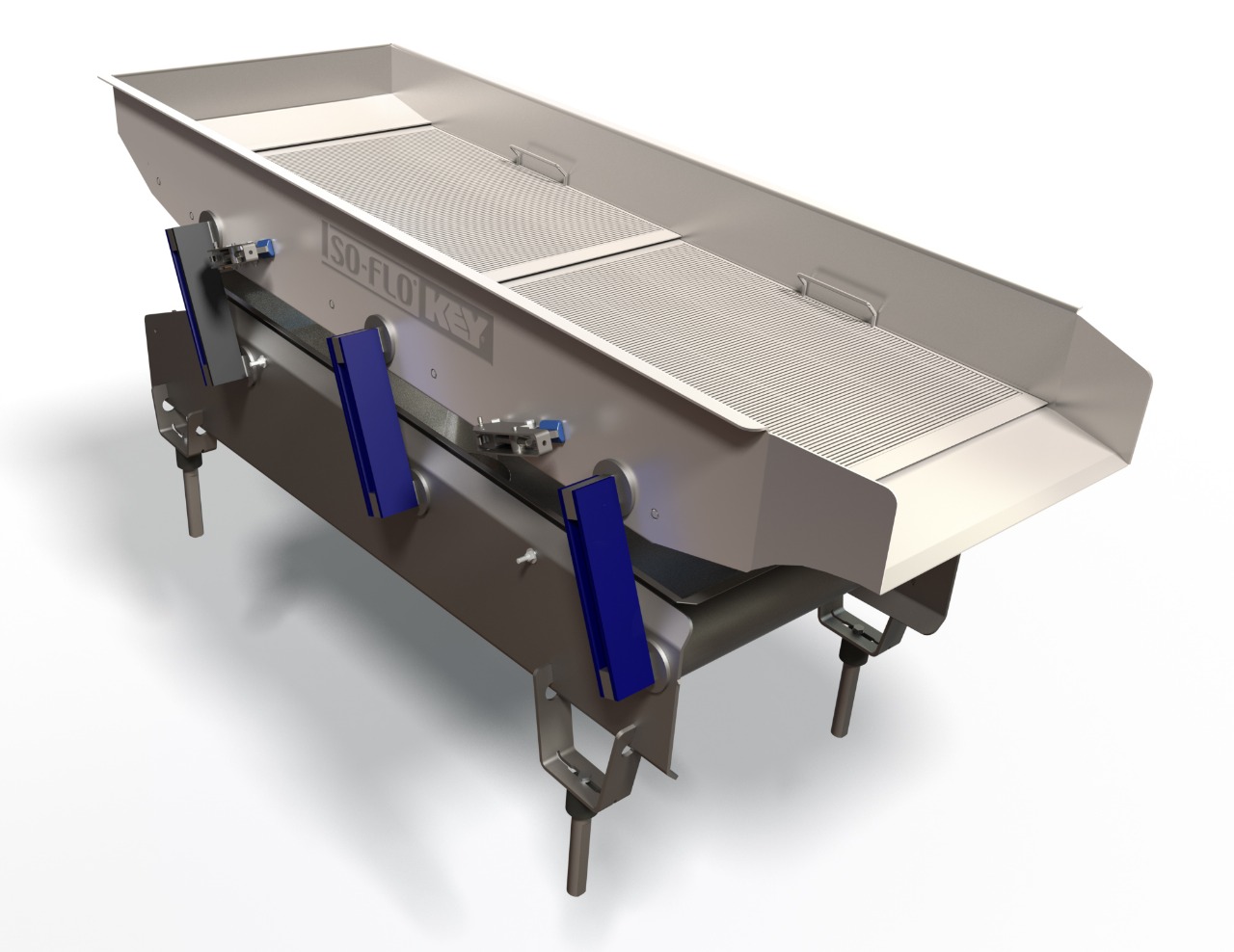

Vibratory Conveyors

Vibratory conveyors use controlled oscillating motion to move and sort bulk materials efficiently. Ideal for applications that require the separation, distribution, or orientation of materials like nuts, bolts, pills, or hot castings, these conveyors provide a reliable and energy-efficient solution. The vibration-based movement is gentle enough for delicate products yet robust enough to handle heavy or hot items in industries like foundries, pharmaceuticals, and manufacturing.

At Robomecs, we specialize in vibratory conveyor systems designed to meet the specific needs of bulk material handling, providing versatile solutions across industries that prioritize efficiency, durability, and flexibility.

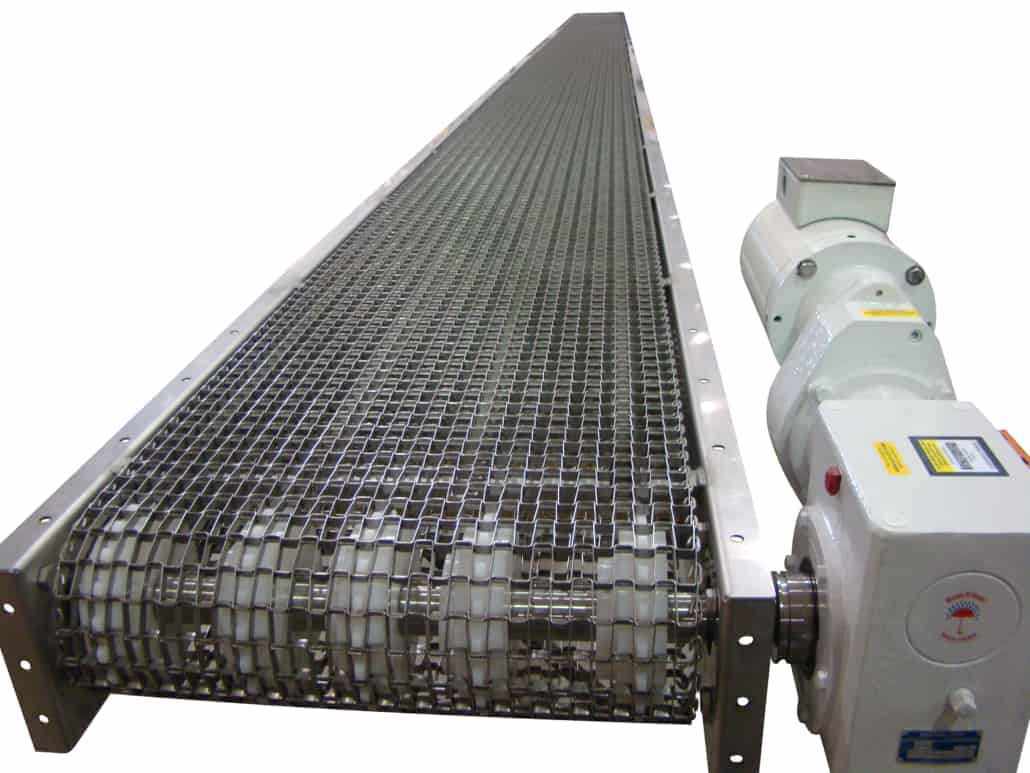

Pneumatic Conveyors

Pneumatic conveyors are ideal for handling materials like flour, cement, or plastic pellets, efficiently moving these substances through pipelines using air pressure or vacuum, eliminating the need for traditional conveyor belts or mechanical handling systems.

Dust-Tight Systems for Clean Environments:

Pneumatic conveyors are designed with dust-tight features, providing a sealed environment to prevent contamination. This is particularly crucial in chemical plants, food processing, or pharmaceutical industries, where product purity and safety are paramount.

Incline/Decline Elevators

Incline/decline elevators provide an efficient solution for transporting products between different levels in industrial settings, minimizing floor space usage while maintaining product stability. These elevators are especially useful in environments where there’s a need to navigate steep elevation changes, such as in recycling centers, bulk material processing facilities, or multi-level distribution centers.

At Robomecs, we specialize in providing customized incline/decline elevators that are designed to ensure smooth and secure product handling during elevation shifts, ideal for various industries requiring vertical logistics solutions.